Jobs move from country to country because of cost and competence. The costs of labour, power, transport, raw materials are all part of the decision matrix used in choosing where to locate manufacturing and support services.

But one key equation now having a massive impact on job location is the balance between labour cost and the application of technology to reduce the labour component not just in manufacturing but also in many services.

Application of Technology and Jobs

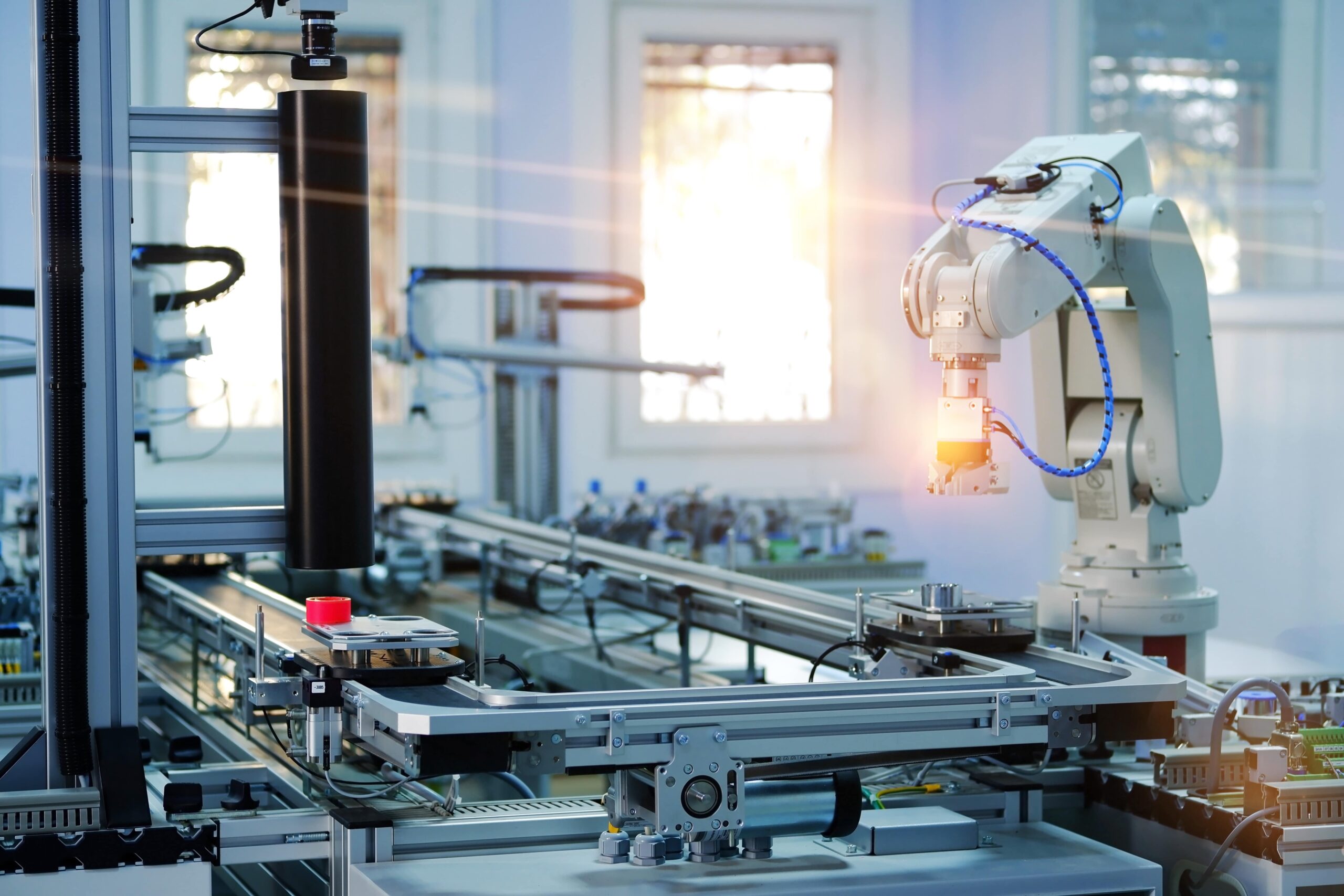

The massively accelerated application of robotics in manufacturing has changed the decision matrix, and low labour costs in developing economies are now being offset by lower labour input costs in developed economies adopting robotics and new materials.

Further drivers for this trend is the requirement for far greater precision in manufacturing, the increasing demand for weight reduction and the need for materials strengthening using highly advanced carbon fibre tech and metal alloys.

For TVET, a revolution in curriculum is required to prepare graduates for an immediate job, but also for continuing employment. Imagine having been trained on extractive technology such as ..cutting, boring, turning using the finest CBM equipment only to find that employment depends on additive technology, the application of 3D printers.

Equally, imagine developing good entry level skills in working with metals when the available jobs are using carbon fibre requiring molding rather than cutting skills. Imagine being prepared for assembly line work and competing with a robot for the job.

Intrusion of Computers into Design

Beyond this, the intrusion of computers into all aspects of design changes the skills required of all new workers in the majority of classic technologies.

The hollowing out of jobs in most manufacturing industries is evidence of this and the primary reason for the migration of jobs from low wage countries back to higher technology countries which they left over the past 20 years.

Increasingly, manufacturing exists in eco-systems of computer control in which all machines talk to each other and share information. A design change is automatically shared with all equipment in the manufacturing process and they adjust to this without assistance.

The internet of things is visible in the integrating of household equipment with a cell phone, but the far greater impact is the linking of all parts of a process within an ecosystem.

IBM, Google, Microsoft, SAS and others are in a foot race against each other to develop these integrated systems that will dominate the workspace. Are we preparing TVET graduates for this environment?

- How do we prepare tomorrow’s graduates for this new world? How does TVET stay relevant?

- How do we afford the changes needed?

- How do we attract the best and brightest young people into TVET institutions?

There is always the concern that new technologies take forever to make it into the job site. Remember the Laser? In 3 decades it moved from the Lab to a pervasive intrusion in almost every aspect of our lives especially in the workplace.

3D printers have begun this process and as industries find applications, they will disrupt not just the workplace, but employment prospects for those without mastery of the necessary knowledge.

How can TVET Educators Respond?

1. Link all education in TVET facilities to industries.

This may involve paying the industry using the newer technologies to do some of the training. The combination of school and O-J-T is already the preferred training model in many TVET colleges and engineering Universities. Planners and legislators need to press hard to achieve this model as quickly as possible.

2. Expand the physics programmes in most TVET training.

Without a basic understanding of the science behind innovation, graduates will never keep up with workspace changes.

3. Increase the commitment to internet based learning.

This is the fastest way to develop the skills required in graduates to keep up with changing technologies in the workplace. As the job-for-life morphs to the Uber-economy of on call jobs, employment will be based on required skills. Period.

4. Change recruitment targets for TVET teachers.

Recruit from the industries that graduates will join. Teachers who do not understand industry, business and the workplace are not useful. Take them in as part time teachers so they still can earn what industry offers.

5. Focus student recruitment on University graduates.

TVET is not for the less gifted. Equally, society demands a University degree if for no other reason, to satisfy parents that they have done their job. Once away from home, unemployed/underemployed grads are flocking to TVET right now. In Canada, many university graduates go to College afterwards to get themselves employed.

6. Rethink TVET institutions programming.

Do the initial design around part time learners who are employed now and let full time students fit in around the vastly restructured timetable formats.

It’s a new world for TVET. Educators will move on, or they will simply become irrelevant.

In many developing countries, the TVET institutions have achieved virtual irrelevancy already as the needs of employers move further and further away from the capabilities and capacity of the institutions.

Recommended articles: